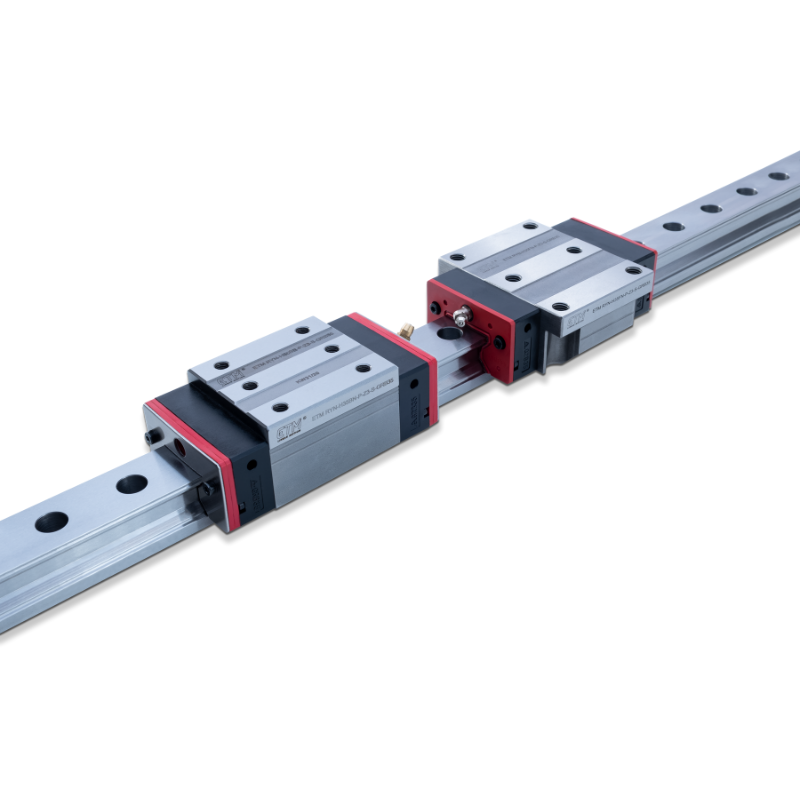

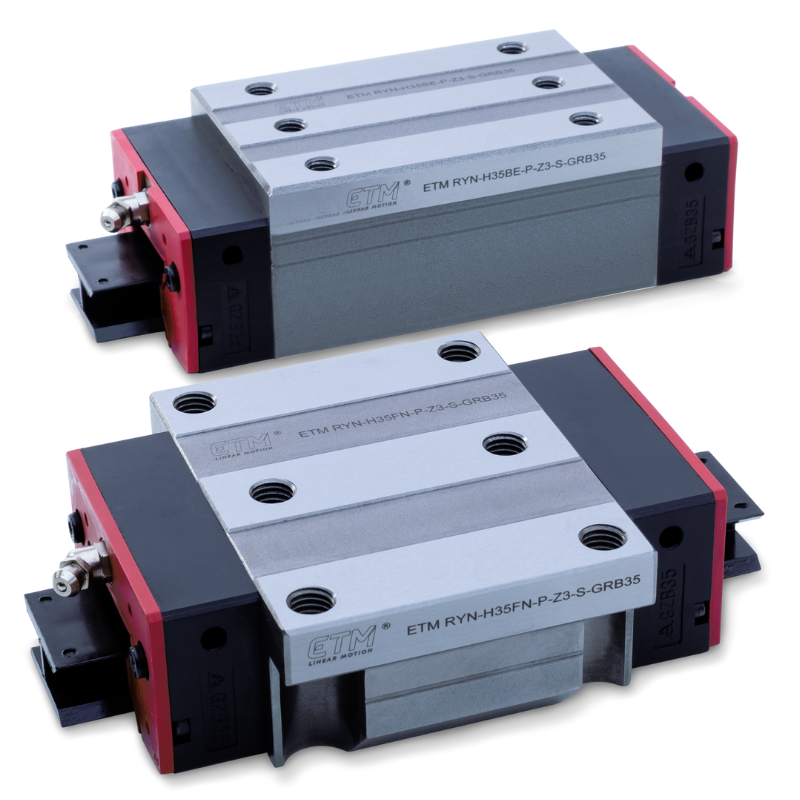

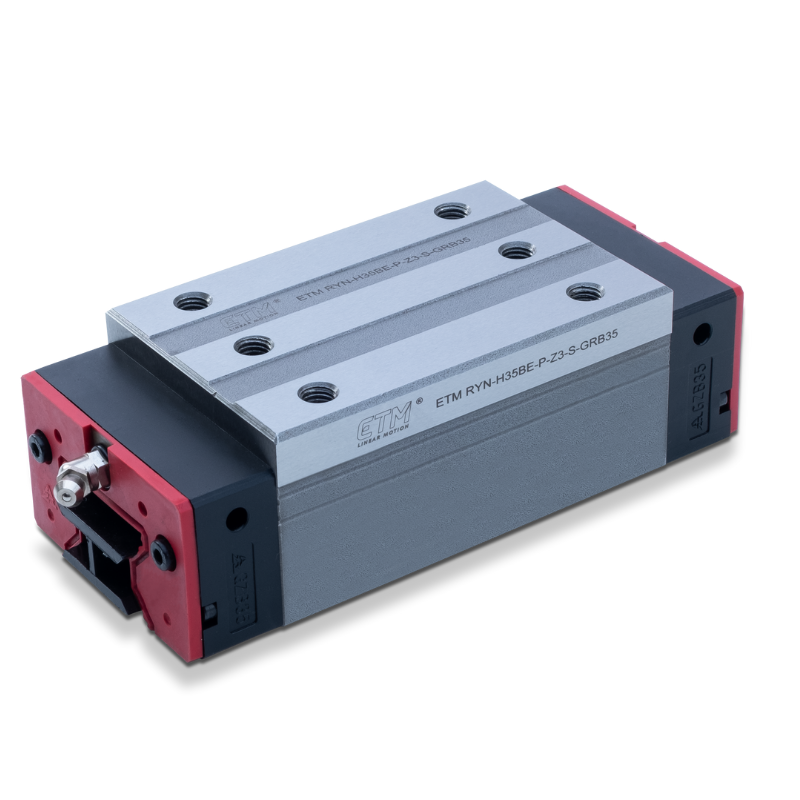

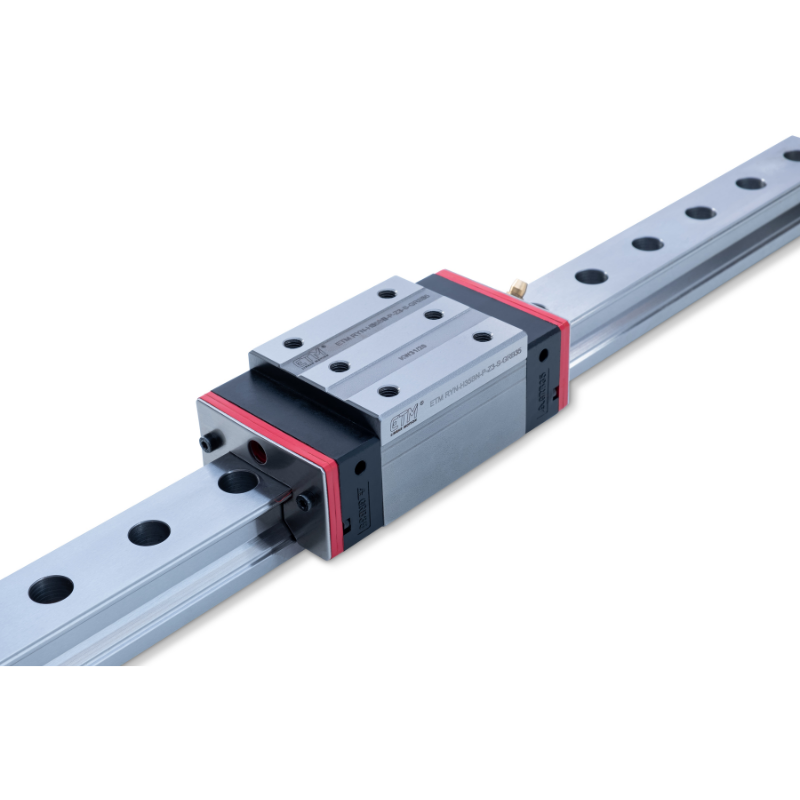

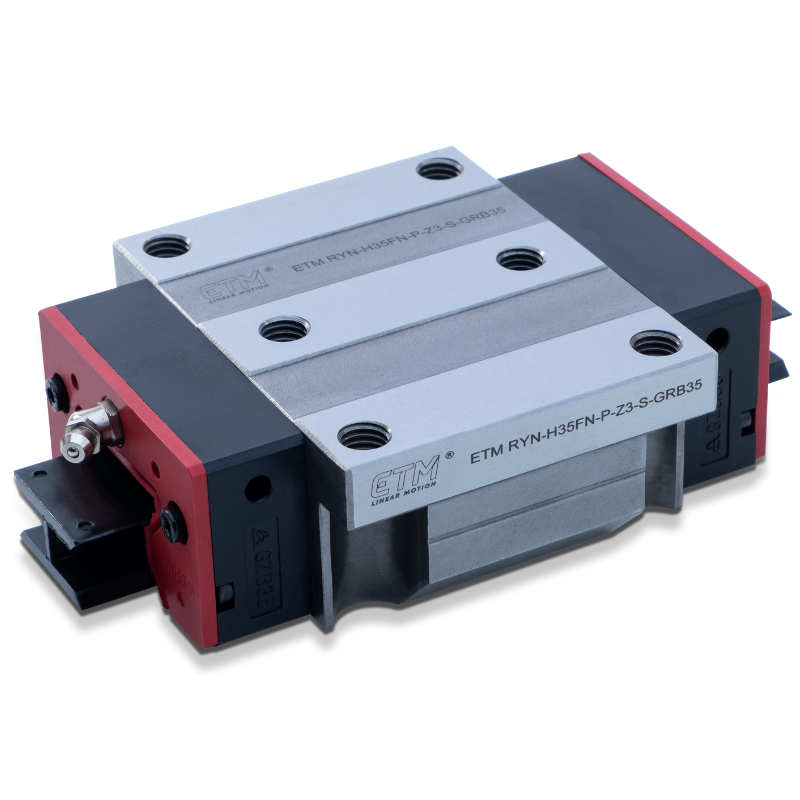

Our assembly geometry provides better load distribution, enabling superior load and moment capabilities. Roller guides have greater rigidity and load capacity when compared to ball guides, as the contact area between the rollers and the rail's rolling track is a line, different from the ball guide which is only a point of contact .

Our guides are fully interchangeable with the main brands on the market and our engineering team works directly with our customers' maintenance sectors.

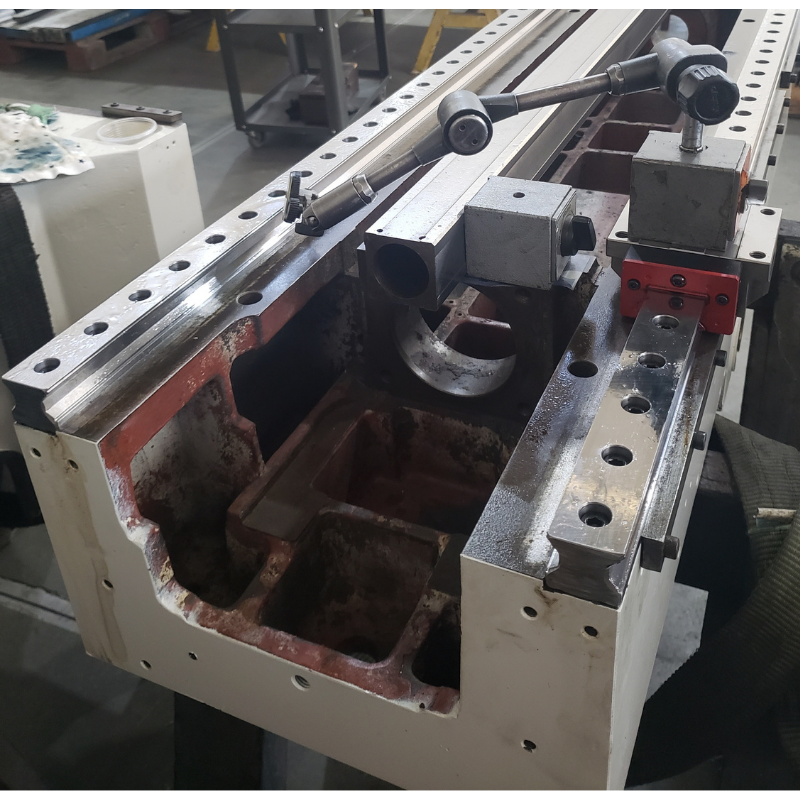

We have great expertise with machine manufacturers and an excellent cost-benefit ratio making your machine competitive.